New Grain & Oil Silk Road Warms Hearts

by SongRan

Early in 140 BC and again in 119 BC, during the Western Han Dynasty, Zhang Qian, a royal envoy and explorer extraordinaire, went on two remarkable journeys. He started from Chang'an, an ancient city in northwest China that was the capital of the dynasty, exploring the route from the East to the West. On his mission, Zhang Qian braved the elements and suffered all kinds of trials and tribulations. But he started a trend of cross-border exchanges, bringing back walnuts, grapes, pomegranates, fava beans and the alfalfa from the Western Regions to China while introducing the Han Dynasty's ingenious karez or underground tunnel irrigation system, silks, tea and iron-making techniques in Sordiana and Dayuan, two ancient countries in Central Asia, and even in the Parthian and Roman empires farther away.

The two journeys 2,000 year ago laid the foundation of the land Silk Road that connected Asia, Europe and Africa and unleashed a spectacular wave of trade and cultural exchanges between China and other countries. Today, agricultural cooperation and trade have once again brought Xi'an, capital of Shaanxi Province and once known Chang'an in history, and North Kazakhstan Region in Kazakhstan closer.

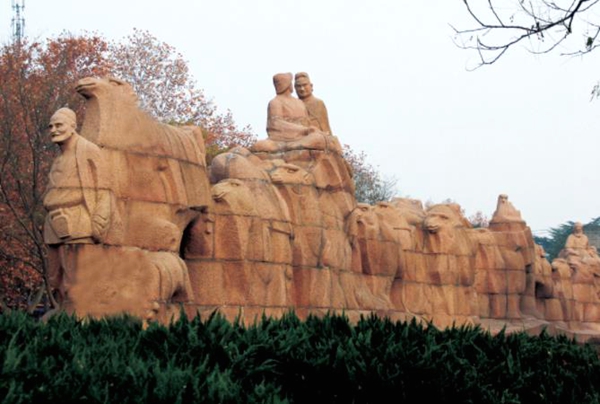

Sculptures of a trade caravan on the Silk Road in Xi'an, China

Amazing Aiju Speed

In early winter in 2016, a modern oil processing plant came up in the vast North Kazakhstan Region, complete with a high drying tower, a spacious raw material warehouse, a processing workshop with modern equipment, an oil cake warehouse and an oil tank workshop.

This was the first phase of an agro-processing and logistics park project jointly built by Xi'an Aiju Grain and Oil Industry Group (hereinafter referred to as Aiju Group) and its Kazak partners. The park is an important logistics hub of Sino-Kazak trade, as well as the Aiju Group's base for transnational production and trade.

Domestically, it covers North Kazakhstan Region and other regions in the neighborhood, and farther and outside Kazakhstan, links with areas in the West Siberian Plain that produce quality agricultural items to import the raw materials, such as wheat and rapeseed, from Russia and Uzbekistan.

The Aiju Agro-processing and Logistics Park in Kazakhstan

It took less than half a year to build and operate the plant with an annual designed output of 300,000 tonnes of processed oil crops. It usually takes two years to build such a plant. The project not only showed speed in construction but also increased cohesion and brought plentiful returns, amazing the North Kazakhstan Region government with its "Aiju speed".

The Aiju speed didn't materialize overnight. The quick construction was the result of the cooperation between the people of China and Kazakhstan who overcame many difficulties. For instance, when the processing workshop was being built, North Kazakhstan Region was going through a rainy summer and the downpours and ensuing mud hampered construction. Still, braving the rain in their heavy raincoats and rain boots, the workers installed the steel structure, tightened the screws, and hoisted the steel. At the end of each day, they would be soaked to the skin despite their raincoats and boots.

The external cables were laid in the freezing winter when the temperature in North Kazakhstan Region usually goes down to minus 30 degrees Celsius and permafrost nearly two meters thick and as hard as reinforced concrete covers the ground. It was a tremendous task to coax the excavator into operation. At times, the force applied to break up the icy layer made the bucket teeth of the excavator crack. Even lighting a fire on the ground to make the ice melt was of no use. In order to complete the project and run it ahead of schedule, the builders had to cut open the permafrost so that the excavator could be used. In this way, concerted efforts were made to fight inclement nature and the inhospitable land and lay the cable in time.

Once the plant went into operation, the Aiju Group moved fast to increase cohesion and ensure returns. It developed an incentivizing reward and promotion system that also respects the local culture and work habits of local employees. It has intensively trained its employees in production knowledge and operating skills to improve their proficiency. In addition, it holds birthday parties for the local staff and helps with their children's education. All this makes the employees feel they are part of one big Aiju family.

At the workshop of the Aiju Agro-processing and Logistics Park

Due to Aiju's scientific management and the hard work put in by the local staff, the plant runs well and the average wage at the plant is higher than in other nearby factories and increases every year. The staff 's quality of life has improved and they feel happy and have a sense of gain. This ensures that they will remain with the company for a long time.

Erkenbeck began to work in the Aiju Park after finishing college. Before that, his father was the sole family breadwinner. He was a farmer and besides the grain sold during the harvest season, the family had almost no other source of income. "But now, my father and I are both working in the park and get a generous salary," he said cheerfully. "We no longer need to do temporary jobs in the city during the slack season, or worry about a steady income." The pair has been working in the park for three years. The living standards of the family have greatly improved, and so has their home.

There are many people like Erkenbeck in North Kazakhstan Region whose lives have been changed by the Aiju Park.

At present, there are 150 employees at the plant. When the second and third phases are completed, the park is expected to create more than 300 direct jobs and over 1,000 indirect job opportunities.

Jointly Fostering Made-to-Order Farming

Sparsely populated Kazakhstan is the world's most important grain-producing country and wheat exporter, with North Kazakhstan Region being one of its three major grain-growing areas. The region is endowed with fertile black soil and favorable natural conditions for growing wheat. However, due to over cultivation, dependence on the weather and lack of advanced agricultural technology and equipment, not many rural residents engaged in farming. As a result, about one-third of the farmland lay idle.

Xi'an residents rush to buy rice, wheat and oil products from Kazakhstan.

The Aiju Group developed a cooperation mode of made-to-order farming. It follows the agricultural land use laws in the region while meeting the market demand. The company signed grain cultivation and purchase contracts with farmers, set protective prices for grain purchasing, and joined hands with Chinese and Kazak research institutions and contractor farmers to adopt a business model covering seed research and development, planting, management, harvesting, purchasing and storage. Made-to-order farming guides farmers in what to plant, how much to plant and how to plant, fundamentally solving the problem of idle farmland and difficulties in selling the grain.

However, made-to-order farming didn't get off to a good start. Aiju spent two months visiting 900 households in 12 nearby villages but less than 100 households signed a contract with them since the farmers were worried about the performance of the seeds that would be provided by Chinese enterprises according to the agreement.

So Aiju and the farmers who did sign the contract cultivated grain in demonstration plots to show how the seeds provided a reliable and quality crop. It also paid an advance to the large farmers to show its good faith. The government of North Kazakhstan Region also strongly supported the initiative and eventually, more and more local farmers joined made-to-order farming.

Balkin is a farmer in North Kazakhstan Region with 20,000 hectares of land. In the past, he used to be worried about the market and the selling price of the grain he grew. However, with the oil processing plant in the Aiju Park becoming operational, his fears have gone. The made-to-order farming has resulted in idle farmland being fully utilized and the harvested grain selling well and Balkin is growing more and more grain. "Aiju showed me the way and gave me assurance. I no longer need to worry about what to plant and the selling price of grain," he said. Since then, he has been recommending Aiju and made-to-order farming to everyone he knows.

The Chang'an Freight Train returns to China fully loaded.

The made-to-order farming cooperation mode has been boosted by the launch of the Chang'an freight train service of China Railway Express from Xi'an to Central Asia, which has shortened transport distances and improved transport efficiency. Aiju's unique container shipping method for bulk grain has also helped reduce transport costs and time. The time needed to send raw materials including wheat from Kazakhstan to Xi'an has been cut down from 25 days to 10 days and the transport capacity has increased from 21 tonnes to 27 tonnes per container.

It now takes Balkin's wheat 10 days to reach Xi'an on the Chang'an freight train and three days for processing and inspection at the Staple Food Industrialization Base in Xi'an's Chanba Ecological District, after which it enters Xi'an's supermarkets.

The Chang'an freight train brings back quality wheat, edible oil, eggs, milk, honey, beef and mutton from Kazakhstan, and has increased the exports of the two countries, enriched the products and created a win-win situation. Kazakhstan has aligned its "Shining Path" national development policy with the China-proposed Belt and Road Initiative to create a promising future for the country.

Jointly Building a Warm Region

Aiju has not only brought tangible gains to the people of North Kazakhstan Region but also shown its corporate social responsibility through its charitable work.

In 2017, after Aiju bought a granary in a village in the region, it heard that the only school in the village was housed in a primitive structure built in the early 1960s and in bad need of repair. The heating ran on pipes that had eroded with years of use and had cracked in places. The cracks couldn't be repaired and the school had papered them over with duct tape. But it was ineffective and the heating system practically served no function, leaving the children shivering in the classrooms in the bitterly cold winter of Kazakhstan.

Aiju supports these students from impoverished families.

Aiju installed a new heating system in the school before winter came so that the children would have a warm and comfortable environment for their education. The school fence had disappeared and Aiju also installed fencing for the security of the nearly 100 students.

The company has done other things as well. Every year, its staff purchases school supplies for the students in the school who come from impoverished families and also pay their school fees. They also regularly visit the elderly with constrained means and offer financial help to impoverished single mothers. The local government and the school present the company with certificates of merit annually to thank it for its contribution to the school and the village.

Over 2,000 years ago, the ancient Silk Road, starting from Chang'an, had built a bridge for trade and exchanges between China, Central Asia, West Asia and Europe. Two thousand years later, there is a new link. The Belt and Road Initiative has crossed mountains and rivers to connect more regions. Peaceful cooperation, openness and inclusiveness, mutual learning and win-win cooperation were the prevailing trends in the past. They have continued in the present too under the aegis of the new initiative.

FOR MORE

Project Overview:

The 333.33-hectare Aiju Agro-processing Park in Kazakhstan began construction in 2016 with a planned total investment of RMB1 billion (USD141.3 million). The oil processing plant built in the first phase of the project covers about 10.67 hectares. The plant includes a drying tower, a raw material warehouse, a processing workshop, an oil cake warehouse, an oil tank workshop and other supporting facilities, with an annual designed output of 300,000 tonnes of processed oil crops. Its granaries can hold 50,000 tonnes and four special railway lines connect the plant, enabling it to sign made-to-order farming contracts with more than 20 Kazak farmers.

Since its completion, the Aiju Agro-Processing Park has become a hub of overseas production areas, an important logistics hub of Sino-Kazak trade and a key halt for China-Europe freight trains. Domestically, it covers North Kazakhstan Region and other regions in the neighborhood, and farther and outside Kazakhstan, links with areas in the West Siberian Plain that produce quality agricultural items to import raw materials, including wheat and rapeseed, from Russia and Uzbekistan.