The Arctic's Energy Pearl

by Xi Yuan

[Russia] Osipova Natalia Mikhailovna

Li Lin has not seen the sun for days as it is winter at the site of the Yamal liquefied natural gas (LNG) plant in Sabetta, where he works. In winter, the sun doesn't rise for over two months in the Arctic Circle, and Sabetta is such a town in northern Russia, 400 kilometers north of the Arctic Circle.

Li's Arctic overalls are quite heavy to keep him warm. But if he stays outdoor too long, his body will still be frozen and his face hurts as if slashed with a knife. Still Li, one of the first managers from China National Petroleum Corporation (CNPC) stationed at the North Pole construction site, is proud to participate in the LNG project and "witness and make history." In his eyes, the plant is doing a fantastic job.

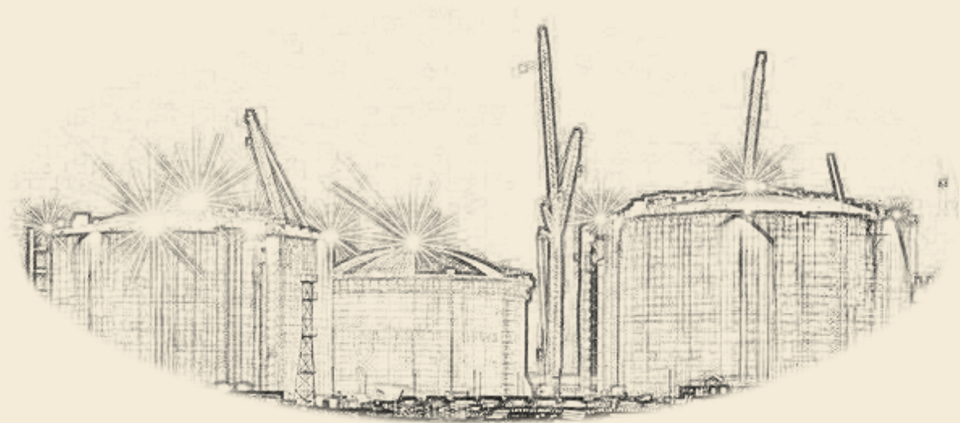

The Yamal LNG plant

Making Impossible Possible

The Yamal LNG plant is located in the Yamal peninsula, far north of Nenets Autonomous Okrug. In the ethnic Nenets people's language, "yamal" means "land's end". In the mid-1900s, geological explorers discovered this vast expanse of ice was sitting on the world's largest natural gas reserves. The huge reserves, shallow in depth and containing high-purity natural gas, account for more than 80 percent of Russia's total natural gas reserves.

However, the extreme geographical and climatic conditions in the polar region prevented access to this treasure. In the wasteland 400 kilometers north of the Arctic Circle, where the Yamal LNG plant is located, the weather is freezing. In winter, the average temperature drops between minus 20 degrees and minus 40 degrees Celsius and can even fall to minus 52 degrees Celsius. The polar night lasts 88 days when there is no sun. Even in August, the warmest month, the average temperature is minus 3 degrees Celsius. During summer, there are 103 days of uninterrupted daylight, making one's head spin.

Workers of the Yamal LNG project

It is never an easy task for humanity to conquer the Arctic. Russian President Vladimir Putin once said that since work started on the Yamal project, the naysayers came up with a long list of the reasons why they thought it was bound to fail.

To make the mission impossible possible, the four major shareholders of the project – Novatek of Russia, Total S.A. of France, and CNPC and the Silk Road Fund of China – founded the Joint Stock Company Yamal LNG and invited builders from a dozen of countries for international cooperation so that the oil and gas reserves under ice in the freezing Arctic coud be explored efficiently.

At the plant, the builders speak many languages – Russian, Chinese, French, English and more, since Sabetta has become an international cooperation platform.

Due to the harsh conditions in the frozen desert, such a megaproject construction was unprecedented in human history. Novatek's CEO Leonid Mikhelson, who was once the chief engineer of a company that builds oilfields, called a coordination meeting of the leaders of all sides to find a solution to the technological problems. The experts proposed modular construction.

It meant breaking down a part into different units or modules, which would be manufactured in factories across the globe, and then shipped back to the construction site in Yamal for installation. This building-block-by-block approach effectively solved the difficulties of on-the-spot construction.

Seven Chinese enterprises, including CNPC, China National Offshore Oil Corporation, Sinopec and Qingdao McDermott Wuchuan Offshore Engineering Co., undertook to build 120 of the 142 modules required. The total weight of the 120 would be more than 400,000 tons. The biggest module was 7,500 tons, almost as heavy as the Eiffel Tower.

But thanks to the innovative model and joint efforts of the engineering teams from different countries, the project progressed faster than expected, outpacing the LNG projects in tropical and subtropical regions, where construction is possible throughout the year.

In December 2017, Yamal's first production line went into operation and on July 19, 2018, the icebreaking LNG carrier Vladimir Rusanov arrived at the LNG receiving terminal in Rudong County in east China's Jiangsu Province, where the temperature was a contrasting 40 degrees Celsius. The vessel carried 75,000 tons of LNG from Yamal. This maiden voyage was a critical moment in the history of Sino-Russian energy cooperation. In August 2018, Yamal's second production line became operational, followed by the third production line in December the same year, a year ahead of schedule.

A Touchstone Project

In 2017, the construction site had been sunless for days during the polar night. Xu Shengjun, deputy director of the Yamal plant’s capital construction department, and his colleagues from other countries walked in steady steps towards the plant in the light of the aurora borealis. They were weighed down by their polar uniform, helmet, shoes, gloves and goggles, which weighed tens of kilograms.

They had arrived at the plant after taking two flights for more than 10 hours. To ensure the greatest work efficiency in the sub-zero temperature, they had to get ready for work immediately after arrival. Once the work started, there was no time for regular meals. They were served Russian cold meals. The bread was so hard that it was too tough to bite into. Though their protective clothing kept their bodies warm, their faces would freeze and they would take turns to warm themselves up. A thick layer of frost encrusting their faces – this became the daily image of the Yamal staff.

The first icebreaking carrier Vladimir Rusanov sails out of the Arctic bearing LNG from the Yamal plant, December 2017.

Nevertheless, they overcame the physical and mental challenges posed by the North Pole, and completed the construction, which, despite made easier by modular construction, was still hard.

At the same time, manufacturing the modules outside the Arctic was equally challenging as there were a huge variety of and a large number of components. They all required high precision and complex techniques, which was far more difficult than the other projects in the industry. To build the 36 core modules, the Chinese companies had to lay 215,000 meters of pipeline, equivalent to the length of the Sixth Ring Road in Beijing. Besides, they had to install 3,300 kilometers of cables, which was long enough to connect Beijing with the Arctic Circle. The files detailing the completed work ran into more than one million pages.

In spite of the difficulties, the Chinese enterprises participating in the construction were the first contractors to deliver the LNG modules, on schedule and with the quality guaranteed. In addition, they created a new safety record of working 38.63 million hours on a single item at a single site without any accident. It set a new benchmark in international building history.

To transport the modules to the Arctic, Chinese shipping and shipbuilding enterprises produced a series of firsts.

Guangzhou Shipyard International Co. built AUDAX, the world’s first polar heavy load carrier. It was 206.3 meter long, bigger than two football fields, and could transport a modular of more than 10 stories high. AUDAX could sail at the super low temperature of minus 50 degrees Celsius, carrying LNG modules to Sabetta. Its icebreaking ability is higher than Chinese icebreaking research vessel Xue Long’s and meets Russia’s highest ice class standard Arc7.

Chen Ming, Chinese professor and top constructor, flew to Yamal with his team to direct logistics for the giant modules, working at minus 50 degrees Celsius on a vast expanse of white ice in the North Pole. From all over the world, 142 giant modules were being shipped to the North Pole and a slight error in their arrival sequence would cause serious congestion in the port, affecting others. This kind of work had never been done before and Chen had to be extremely careful.

The office and residential area at the main campsite

Putting their research into practice, Chen and his team improved the transportation plan and meticulously organized the complex logistics to tightly coordinate the construction process. During the years of construction, he became a frequent flier, flying from the seven domestic module manufacturers to Moscow and back almost every month.

With his colleagues from all over the world, Chen made large-scale use of the Northeast Passage, the shipping route to the Pacific. More than half of the modules and goods were sent to the construction site via the passage, which remarkably reduced transport costs.

The Yamal LNG project can be called a touchstone of perseverance, dedication and professionalism, as well as courage to make innovations and overcome difficulties. The people on the job worked in freezing temperatures and without any precedential experience to draw on when they faced unforeseen complex factors. A model of international energy cooperation in the Arctic, it is a milestone in international pragmatic cooperation.

Radiating Positive Energy in Ice and Snow

At the 5th China-Russia Expo held in Yekaterinburg in Russia in July 2018, the Yamal-Nenets Autonomous Okrug booth presented an arresting sight. Its fur tents, display of ethnic clothes and deer models brought elements of the mysterious Arctic with its vast tundras. The pristine region has remained unchanged for thousands of years, and the builders of the LNG project had to ensure that no harm would befall the region during their work.

The project, besides its commercial successes, also took meticulous measures to ensure the Arctic ecology was protected.

It undertook construction following the Equator Principles, the framework used by corporate institutions to assess and manage environmental and social risks in their projects. The standards followed at Yamal were higher than national and general business standards. The drilling cuttings, mud and waste liquid generated during construction and operation were treated comprehensively to mitigate environmental damage. Yamal LNG invested over USD40 million to build a recycling station for the mud produced during drilling, using environmentally friendly technology in the Arctic.

To save energy and reduce emissions, a campsite was built at the site. It can accommodate 30,000 people and has greatly improved commute, living and food conditions for the staff. While meeting environmental and work requirements, it also embodies a peopleoriented concept.

A bird's eye view of the Yamal LNG project

The Yamal LNG project has its roots in the Arctic. It has honored that by developing the region and meeting the needs of the local people.

It has built a kindergarten, a boarding school for the children of the nomadic local tribes and a church. There have been other infrastructural benefits for the community like a water treatment facility, a small power station, a hospital, a venison processing plant and apartments. It also collaborates in science and innovation with the Arctic Research Center, has sponsored a international forum for indigenous people, and taken part in public welfare activities including supporting veterans in Yamal.

The project has been localized as far as possible without compromising on technology and cost control. During construction, Yamal LNG signed contracts worth USD10 billion with 650 enterprises in 55 Russian federal areas, creating more than 60,000 jobs.

At the end of 2018, the Yamal LNG site had become a brilliantly illuminated area full of people. Due to the joint efforts of all the players, the three production lines of the project were put into operation ahead of schedule. Builders of different nationalities embraced one another, celebrating the realization of common goals.

With the development of the Yamal LNG project, more and more people are venturing to cross the polar circle, visiting the plant and living in tents. The project protects the unique ecology of the Arctic while illuminating the night sky, a symbol of international cooperation with bright prospects.

FOR MORE

Project Overview:

The Yamal LNG project is located in Russia's Yamal Peninsula. It is the largest LNG project in the Arctic, exploring and developing natural gas and condensate oil, natural gas processing and liquefaction, and maritime transport and sales.

It is also a pioneer in the development of the Arctic, with Chinese companies as an important investment and construction partner. China National Petroleum Corporation is engaged in project operation while other Chinese enterprises are involved in engineering, logistics, shipping and marketing. They have also undertaken 85 percent of all the modular construction.

Currently, Yamal LNG is the largest economic cooperation project between China and Russia and has received positive evaluation from the leaders of both countries.