Sunmaker Contributes to African Youth's Future

by Ren Feifan

[Uganda] Aiayo Fiona

In the urban area of Kampala, the capital of Uganda, a new red-and-white two-storied building stands out on the yellow ground. On a working day, groups of black youths in neat uniform, white safety helmets and black boots can be seen trooping in and out of the building that is a training institution founded by four Chinese.

The Sunmaker Oil & Gas Training Institute, established in 2017, has trained more than 2,000 industry professionals for Uganda. Besides hardware, it offers training in oil and gas industry-related skills, safety, theory and management. The courses, poplar with the locals, have contributed to improving the skills of African youths.

A Life-Changer

Sam, a 26-year-old Sunmaker graduate, runs a welding workshop where he employs five people. The workshop mainly produces iron beds, doors and windows, and railings. While the local average monthly salary is about 400,000 Ugandan shillings (USS105.90), Sam has a monthly income of 3 million Ugandan shillings (USD810). He leads a relatively prosperous life, especially given the fact that 60 to 70 percent of young locals are unemployed.

Sam attributes his success to his training at Sunmaker. However, when he enrolled for the training, he was doubtful about the prospects. He was not sure what kind of school it was and what he could learn there. He was also doubtful if he would be able to follow the teaching methods of the Chinese trainers. However, once the training began, his doubts were dispelled and he says he learned new things every day.

To teach the trainees the most advanced welding techniques, the institute brings top welding trainers from China. To ensure the trainees understand the instructions, professional interpreters are hired for the trainers.

Sam received a shock when he went to the practical training site. The institute provided ample welding rods for all the students to practice welding. The rods were imported and therefore very costly. Other training schools could only afford a few rods every six months. Sunmaker spared no cost to ensure its students had sufficient practice.

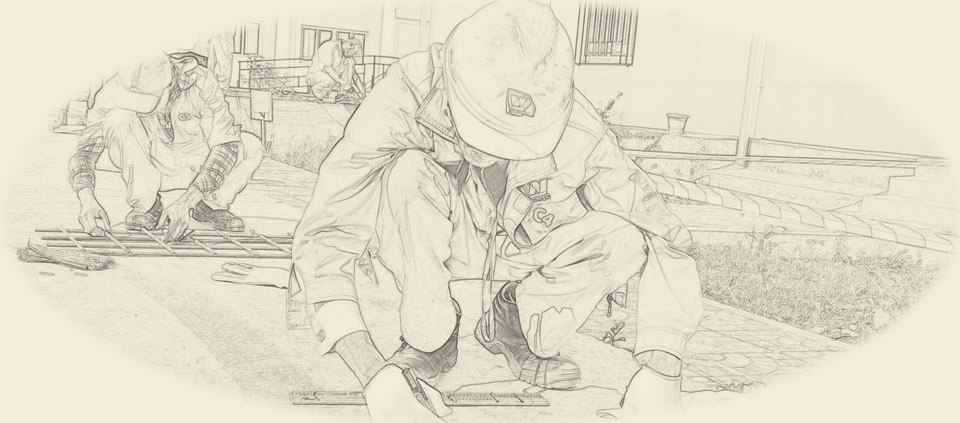

The trainer and his apprentices at an international welding training class

Every morning, the trainers handed out the materials, and the trainees started working on them in groups of three. The trainers provided targeted guidance. After the tasks were completed, they would call all the students and provide overall instructions on common problems. The training mode and methods were intensive and very effective. Sam's technique improved considerably and after the course, he obtained a manual welding certificate from the American Welding Society, something that he could not even think of in the past.

After graduating from Sunmaker, Sam thought of starting his own business since the quality of civil welded products on the market was questionable with the parts often breaking. He borrowed money from his relatives and friends, bought a welding machine and started his entrepreneurial journey. The skills learned at Sunmaker helped him build up a reputation, eventually leading to his current prosperity.

When he thinks of the time he spent at Sunmaker, Sam thinks it was a time that changed his life. In just three months he set himself a goal and his future became clearer. Earlier, he had never planned his future. His next plan for the future is to expand his business and have 20 employees in a year or two. Whenever he talks about this goal, his self-confidence is palpable.

Sam's batchmates at Sunmaker have also benefited from the training program. After they completed the course, all 30 students of that batch got jobs against the expected employment rate of 30 percent. Their salaries are two to three times that of other local welders. Fourteen of them were hired by Chinese companies in Uganda, 12 went to local companies, two became trainers, and two started their own business.

Vicente and Julius, who were Sam's batchmates, also have bright prospects. After the welding training was over, Vicente participated in the first Skills-Uganda Program, a national skills competition hosted by the Uganda Ministry of Education and Sports, and won the first place in welding. Julius represented Uganda at the first African Skills Competition organized by WorldSkills, a Netherlands-based organization that organizes world championships of vocational skills, and won the second place in welding.

Bridge Between Workers and Companies

In recent years, there is a strong demand for skilled personnel in Africa due to the boom in infrastructure development. However, skilled workers account for only 0.5 percent of the local population. On one hand, a large number of young people in Africa are unemployed, and on the other hand, it is difficult for enterprises to recruit skilled workers. High-quality vocational training is urgently needed for Africa's development.

In 2017, Sunmaker's startup team surveyed some African countries with the aim of launching training programs. After a comprehensive review of the conditions in several countries, it selected Uganda as its first stop in Africa.

There were few vocational institutions in Uganda and these were either inadequately equipped or lacked good trainers. Though international aid programs had donated several machines to these institutions, they lay idle, gathering dust. Some had not even been unpacked even though they had arrived several years ago, let alone be used for training.

Sunmaker has met Uganda's need for technicians. One example is Victoria, a local company specializing in welded street lamp fixtures. Not long after Sunmaker was set up, it was approached by the Ugandan company asking for its employees to be trained.

A trainer and his apprentices at a training program for Victoria discuss welding skills

Although Victoria had been in business for many years, due to its underdeveloped technology, its product line was relatively simple and its growth slow. It urgently needed to improve the welding skills of employees and manufacture better quality products to cash in on Uganda's rapid economic growth and increase its market share.

According to Victoria's in-charge, although Sunmaker was a new institution, it had a strong faculty and advanced equipment. “I really appreciate their training that combines theory and practice. After visiting several vocational schools, I chose Sunmaker without hesitation,” the in-charge said. “I hope the training will improve the welding skills of our employees and lay the foundation for the company's product diversification and market expansion.”

After learning about the technical condition of the company, Sunmaker designed an overall training plan for its employees, including a special one-on-one training program. The three-month training improved the skills of the 16 welders of the company remarkably. In the past, a welder could weld only three street lamp fixtures a day; now the number has gone up to 10, and the monthly output value has increased by 60 percent. Victoria's product line has also expanded from street lamp fixtures to large-sized pipes and closed containers.

Sunmaker has signed memorandums with a number of local companies in Uganda to cooperate on technical training. It has also reached preliminary agreements with Uganda's Ministry of Education and Sports and China University of Petroleum to jointly build an East Africa Petroleum Skills Training Center.

Like a Family

Edith, a local employee of Sunmaker, looks after the internal operation of the entire training program, from course scheduling and communicating with the trainers to students' accommodation and catering quality.

In early 2019, Edith's mother was diagnosed with cancer and had to be hospitalized. The medical expenses were huge for a young woman who had just started to work. However, after learning about her difficulties, the school helped with the treatment costs. When Edith's mother succumbed to the disease, the institute arranged for the local staff to help with the ensuing formalities and gave her unstinting support.

Edith is now back at work with a more positive attitude. She is ready to go forward with her life and has applied for a postgraduate program at Makerere University, Uganda's largest and oldest university, which will open a new door for her future. She often says, “Sunmaker is like my family.”

The Sunmaker Oil and Gas Training Institute in Uganda

When Sunmaker trainees talk of Edith, they echo her feelings about Sunmaker, saying they too have received not just training at the school to improve their skills but the warmth of a family. This is what a trainee wrote in the graduation album, mentioning Edith and drawing loving hearts around her name. In the big family of Sunmaker, many young people began as students and some of them became backbone teachers from university students with no teaching experience. Some have grown from cleaners into corporate executives.

The motto of Sunmaker is “Using the energy of knowledge to develop material energy and create a new sun”. The Chinese entre- preneurs who set it up are spending the prime of their life in Africa to break new ground with Uganda's young people. Sunmaker's unique entrepreneurial model of overseas vocational education epitomizes deeper, more diversified China-Africa cooperation.

FOR MORE

Project Overview:

Sunmaker Oil & Gas Training Institute was founded by four Chinese doctorates from Peking University, University of International Business and Economics, and China University of Petroleum. It is committed to enhancing Africa's endogenous development by improving the skills of African youth, changing the human resources structure in Africa, and thereby enhancing the ability of African countries to develop independently. Headquartered in Uganda, it has offices in Kenya, Tanzania, Ethiopia, Nigeria and other countries.

Built in June 2018, the 1.2-hectare Sunmaker Oil & Gas Training Institute encompasses office and training areas, which can accommodate 600 people for the classes, and a living area where 200 people can be accommodated. It offers courses in four major areas: skills and operation, petroleum engineering, management, and QHSE (quality, health, safety and environmental protection) management system. A total of 28 training programs have been completed and more than 2,000 people have been trained.